The Belcher family has been producing top quality maple syrup for over 60 years. This tradition began during the rationing period of World War II when many commodities, including sugar, were in short supply. As a means to supplement the short supply, Les and Betty Belcher, tapped a few maple trees near their Brighton, MI home, and in a cast iron kettle boiled the water out of the sap until it was maple syrup. It was this sweet syrup that was used in place of sugar. The harvest was so successful that they were able to trade some sugar ration stamps for gasoline stamps.

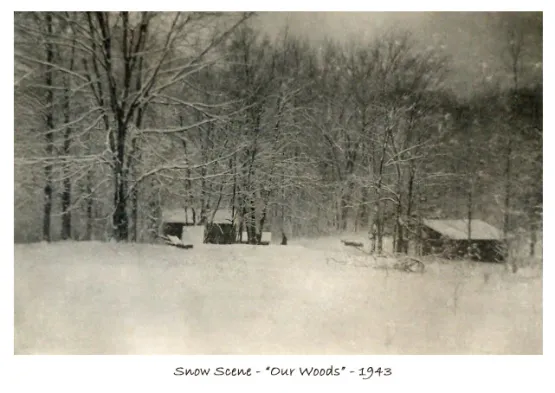

Not long after the war ended, Les and Betty realized the potential in what they had begun. They purchased forty acres of land south of Marion, MI where the Muskegon and Middle Branch River converge, and there they built a small vacation and hunting cabin. Farther back in the woods, they set up a small flat pan for making maple syrup. At this point the harvest was transformed into a money-making hobby. Les began selling the syrup at his Gulf gas station in Hamburg, MI.

What prompted the next move is debatable, but the result is unmistakable. One rainy day during a deer hunting trip at the cabin Les and his hunting partner, Red Terry, set out to look at land for sale, and found a nice 80 acre piece to the west of Marion. This land was beautiful and rolling,and included forty acres of upland hardwoods. Here the maples were sugar maples; not the soft maples that grew in the low lands. Within two years the gas station was sold, the low forty was sold, and Les and Betty were packing for the move “up north.”

A commercial Vermont 5’ x 14’ evaporator was purchased in 1966 and set up in a rough sawed building. The building and evaporator are still in use today. Covered buckets were used until the mid 1970’s when the sap gathering technique was switched to tubing. In 1993, Les’ son Jim took over the maple syrup operation. Jim operates the evaporator in much the same way as Les, using wood fuel as a heat source. Jim says, a wood fire is truly an organic way of making good tasting maple syrup. However, in order to keep up with demand and to help keep costs down, a reverse osmosis machine was installed in 2014.

Jim’s conviction that his maple syrup is of high quality was reinforced at a recent Michigan Maple Syrup Association convention, where he won First Place and Best of Show with his Amber Rich grade syrup.